Materials

Dielectric

Dielectrics are insulating materials deposited or grown on substrates to isolate conductive layers, store charge, or control electric fields within microelectronic and photonic devices.

Silicon Dioxide (SiO2)

This is one of the most useful materials in micro-device development and fabrication because of its excellent insulating, masking, and structural properties. Example applications include isolation between devices or between multi-stacked electrical routing layers, low-loss dielectric in capacitors, passivation to protect devices from contaminants and environmental damage, etch mask for anisotropic etching, dopant barrier during ion implantation or diffusion, and cladding layer in optical waveguides.

We have multiple options for depositing and processing SiO2 and can work with partners to select the optimal process based on application. Deposition processes include Physical Vapor Deposition (PECVD) with silicon-rich or silicon-deficient stoichiometry, sputtering with controlled oxygen content, e-beam evaporation, Atomic Layer Deposition (ALD), and Low Pressure Chemical Vapor Deposition (LPCVD) for dense films. Processing techniques include Inductively-Coupled Plasma (ICP), Reactive Ion Etching (RIE), and wet chemical processing to produce features such as interlayer vias and tapered profile structures. We can develop the material to have tailored properties like tuned refractive indices and intrinsic stress.

Silicon Nitride (Si3N4)

A versatile material in microfabrication, especially valued of its barrier properties, mechanical robustness, and optical performance. It’s uses include waveguide material in photonic integrated circuits, structural components, such as membranes and cantilever in Micro-Electro-Mechanical-Systems (MEMS), moisture barriers, and as the high index component of Distributed Bragg Reflectors. It complements SiO2 in many applications and is indispensable in microelectronics, Micro-Electro-Mechanical-Systems (MEMS), and photonics.

We have multiple options for depositing and processing silicon nitride (Si3N4) and can work with partners to select the optimal process based on application. Deposition processes include Physical Vapor Deposition (PECVD) with silicon-rich or silicon-deficient stoichiometry, sputtering with controlled nitrogen content, and Atomic Layer Deposition (ALD). Processing techniques include Inductively-Coupled Plasma (ICP), Reactive Ion Etching (RIE), and wet chemical processing. We can develop the material to have tailored properties like tuned refractive indices and intrinsic stress.

Silicon Oxinitride (SiON)

A versatile material that blends the properties of silicon dioxide (SiO2) and silicon nitride (Si3N4) by incorporating oxygen and nitrogen atoms into the same amorphous matrix. Example applications include refractive index tunability for graded index optical devices, anti-reflection coatings, and stress-sensitive moisture barriers. Our capabilities include Physical Vapor Deposition (PECVD) and sputtered silicon oxinitride (SiON). You can leverage our experience in this material to develop device component properties that suit your needs.

Tantalum Pentoxide (Ta2O5)

A high-performance dielectric and optical material. Its key characteristics lies in its high dielectric constant and refractive index, making it ideal for applications requiring high-k dielectrics and optical interference films. It also has low optical loss from the visible to near-IR.

Others

Aluminum Oxide (Al2O3)

Titanium Dioxide (TiO2)

Yttrium Fluoride (YF3)

Silicon Carbide (SiC; Physical Vapor Deposition, PVD)

Metal

Metals are conductive materials deposited to form interconnects, electrodes, and reflective layers that enable electrical routing, light manipulation, and signal transmission within devices.

Titanium (Ti)

Platinum (Pt)

Gold (Au)

Nickel (Ni)

Germanium (Ge)

Paladium (Pd)

Silver (Ag)

Copper (Cu)

Chrome (Cr)

Tungsten (W)

Ti-Tungsten (TiW)

Molybdenum (Mo)

Moly-Chrome (MoCr)

Niobium (Nb)

Aluminum (Al)

Solder

Solder can be deposited and patterned at precise locations within device contact pads or substrate vias to form reflowable interconnects and bonding layers for device assembly and packaging. We can deposit patterned solder by physical vapor deposition and lift-off or by stencil screen printing, depending on feature size or application.

Indium (In)

Semiconductor

Semiconductors are materials whose electrical conductivity and refractive index can be precisely controlled, forming the active regions of electronic and optoelectronic devices.

Amorphous Silicon (a-Si)

A non-crystalline form of silicon that has unique electrical, optical, and material properties, making it a vital component of many devices, such as photovoltaics, LCD displays, and medical imaging x-ray and flat panel detectors. It can also be formed into thin film resistors with tailored resistivity for integrated read-out circuits. Amorphous silicon is prized for its compatibility with large-area and low temperature processes.

We have deep expertise in the deposition and processing of a-Si materials, including forming films with controlled dopant incorporation, devices such as p-i-n photodetectors and thin film transistor (TFT) circuits.

Polysilicon (Poly-Si)

An important form of silicon with properties that sit between amorphous and crystalline silicon. The material is composed of many small silicon crystals, and can be intrinsic, doped, or hydrogenated. It offers the versatility of amorphous silicon (a-Si), but with carrier mobility up to 100x higher than a-Si.

Indium Tin Oxide (ITO)

A transparent conducting oxide that is used in applications such as transparent electrodes for displays, solar cells, and vertical-cavity surface-emitting lasers (VCSELs). It can also be used to form thin film resistors and heaters, and can be integrated into waveguides, metasurfaces, and modulators. In biosensor devices, ITO can function as a transparent platform for electrochemical sensing, cell imaging, and surface functionalization.

We can control the oxygen content of ITO films to tailor their electrical and optical properties to your needs.

Gallium Arsenide (GaAs)-Based Heterostructure

GaAs heterostructures are layered crystalline semiconductor structures combining gallium arsenide with near lattice-matched alloys of differing bandgaps to engineer carrier confinement and enhance electronic or optoelectronic performance. GaAs is widely used in high speed electronics, red and near-infrared light-emitters and detectors.

We have extensive experience in the growth and fabrication of GaAs devices.

Indium Phosphide (InP)-Based Heterostructure

InP heterostructures are similar to gallium arsenide (GaAs) heterostructures but are based on the lower bandgap InP material system, suitable for the longer telecom wavelengths.

We have extensive experience in the growth and fabrication of InP devices, including Fe-doped regrowth of InP.

Gallium Nitride (GaN)-Based (Wide Bandgap) Heterostructure

GaN heterostructures combine alloys of wide bandgap epitaxial Indium Aluminum Gallium Nitride (InAlGaN) to form visible LEDs, blue-violet laser diodes, high voltage electronics, and high power, high frequency RF/microwave devices.

We have deep experience growing and fabricating GaN-based optoelectronic devices formed on different types of substrates, such as sapphire or single crystal GaN. We also have experience with laser epitaxial lift-off and subsequent epi transfer to non-native host substrates.

Aluminum Nitride (AlN)-based (Ultra-Wide Bandgap) Heterostructure

AlN heterostructures are similar to gallium nitride (GaN) heterostructure but have higher bandgaps. These characteristics enable higher power electronics and Ultra-violet (UV) photonic devices needed in many quantum systems.

We have deep experience growing and fabricating AlN-based optoelectronic devices formed on different types of substrates, such as sapphire or single crystal AlN substrates.

Organics

Organic films are carbon-based materials, such as photoresists or polymer coatings, used for patterning, insulation, passivation, structural support, or as functional active layers in electronic, photonic, and sensing devices.

- Photoresist – positive, negative, lift-off resist, dry film up to 100 um thick

- SU-8

- Benzocyclobutene (BCB)

- Polyimide

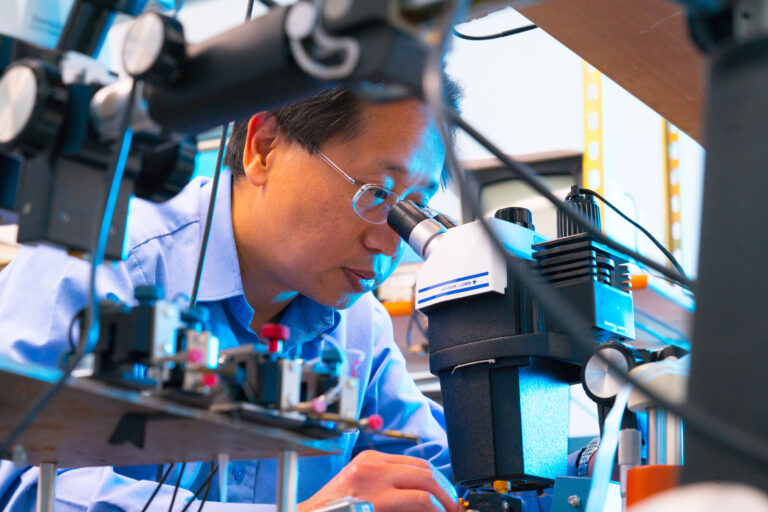

“The PARC/SRI technology was what enabled such good results, with [our devices now] exhibiting 4000-hour lifetimes. Very happy with the interaction.”

YO, Deputy General Manager of Corporate Strategy

Client company manufacturer of semiconductor substrates and optoelectronics devices

On the co-development of Gallium Nitride devices and its subsequent commercialization.