Equipment

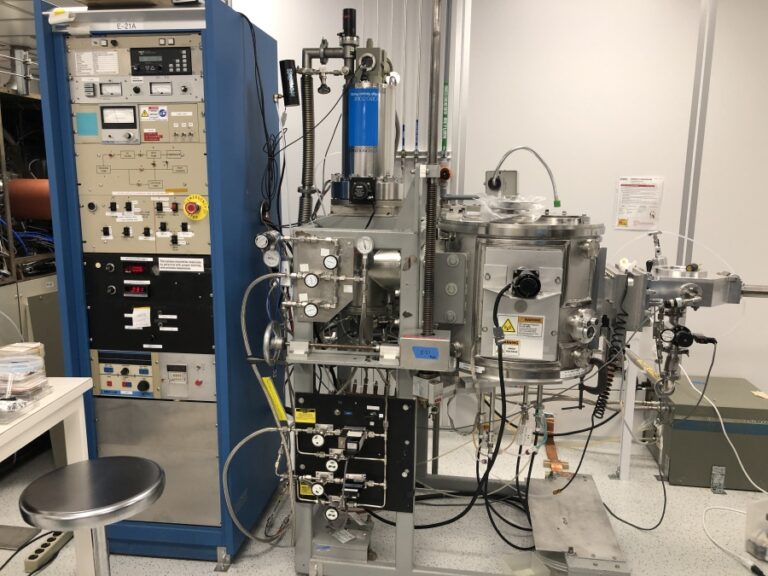

Thin Film Deposition

- Plasma-Enhanced Chemcial Vapor Deposition (PECVD) – single chamber

- Plasma-Enhanced Chemcial Vapor Deposition (PECVD) – multi-chamber, doped materials

- Low Pressure Chemical Vapor Deposition (LPCVD)

- Atomic Layer Deposition (ALD)

- Sputtering – multiple machines for different materials & configurations

- eBeam Evaporator

- Metal Organic Chemical Vapor Deposition (MOCVD) for III-V semiconductor heterostructure (gallium arsenide – GaAs, indium phosphide – InP, gallium nitride – GaN)

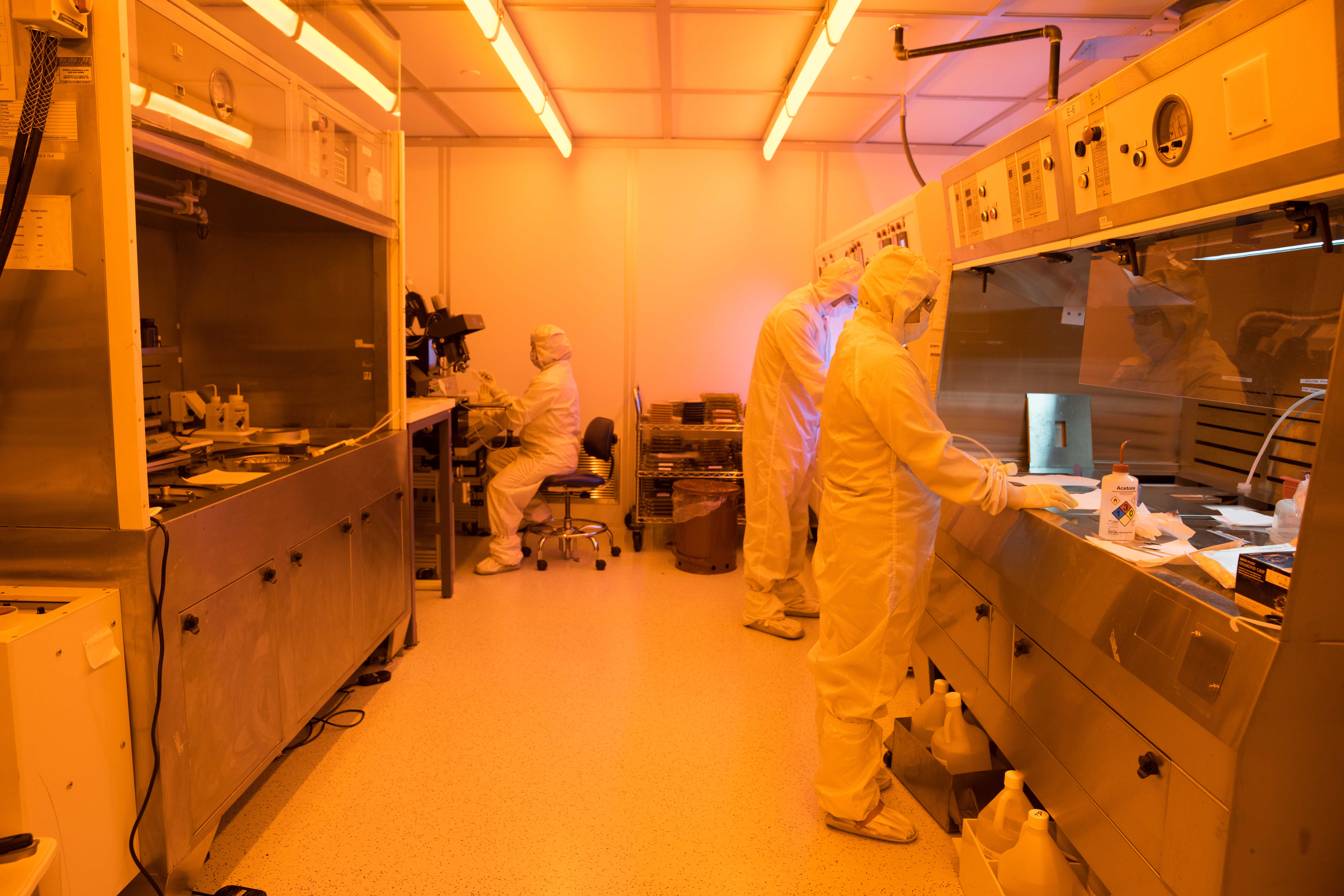

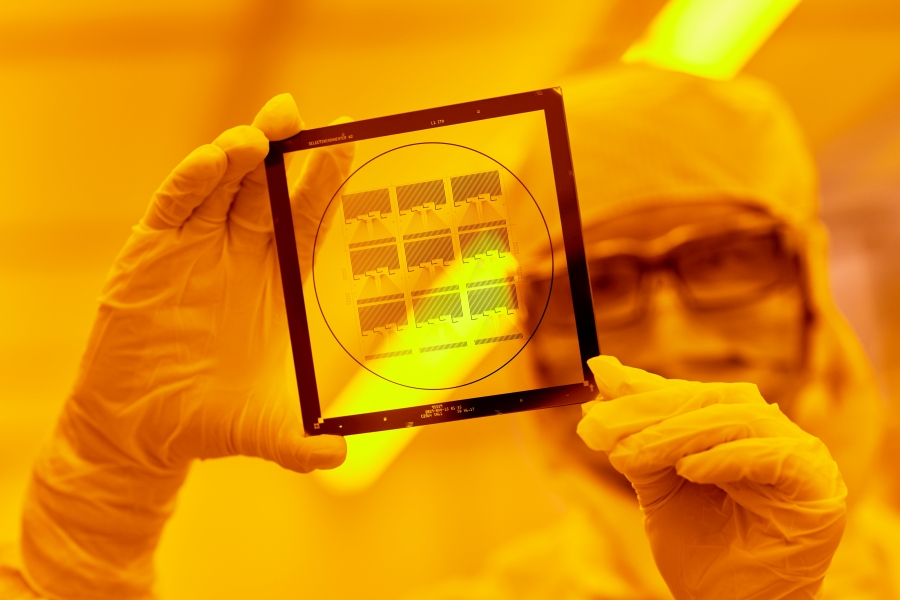

Photolithography

- Contact aligners

- Oxygen (O2) Plasma for descum and photoresist ashing

- Photoresist wet processing stations (spinning, developing, stripping)

- Lift-off stations

- Baking, Hexamethyldisilazane (HMDS), and ammonia (NH3) image reversal Ovens

- Photomask cleaning

Etching

- Chemically-Assisted Ion Beam (CAIBE)

- Inductively-coupled Plasma (ICP)

- Reactive Ion Etcher

- Xenon Difluoride (XeF2) Plasma-less etcher

Thermal Processing

- Various furnaces with controlled ambient

- Vacuum ovens with programmable temperature profiles

- Rapid Thermal Anneal

- Hydrogenation – passivation of processed silicon

- Excimer laser for shallow dopant activation and for forming Low Temperature Polysilicon (LTPS)

Wet Processing

- Various wet bench stations for specialized wet processes

- Electroplating

- Spin rinse dryers – 4”, 6”, 8”

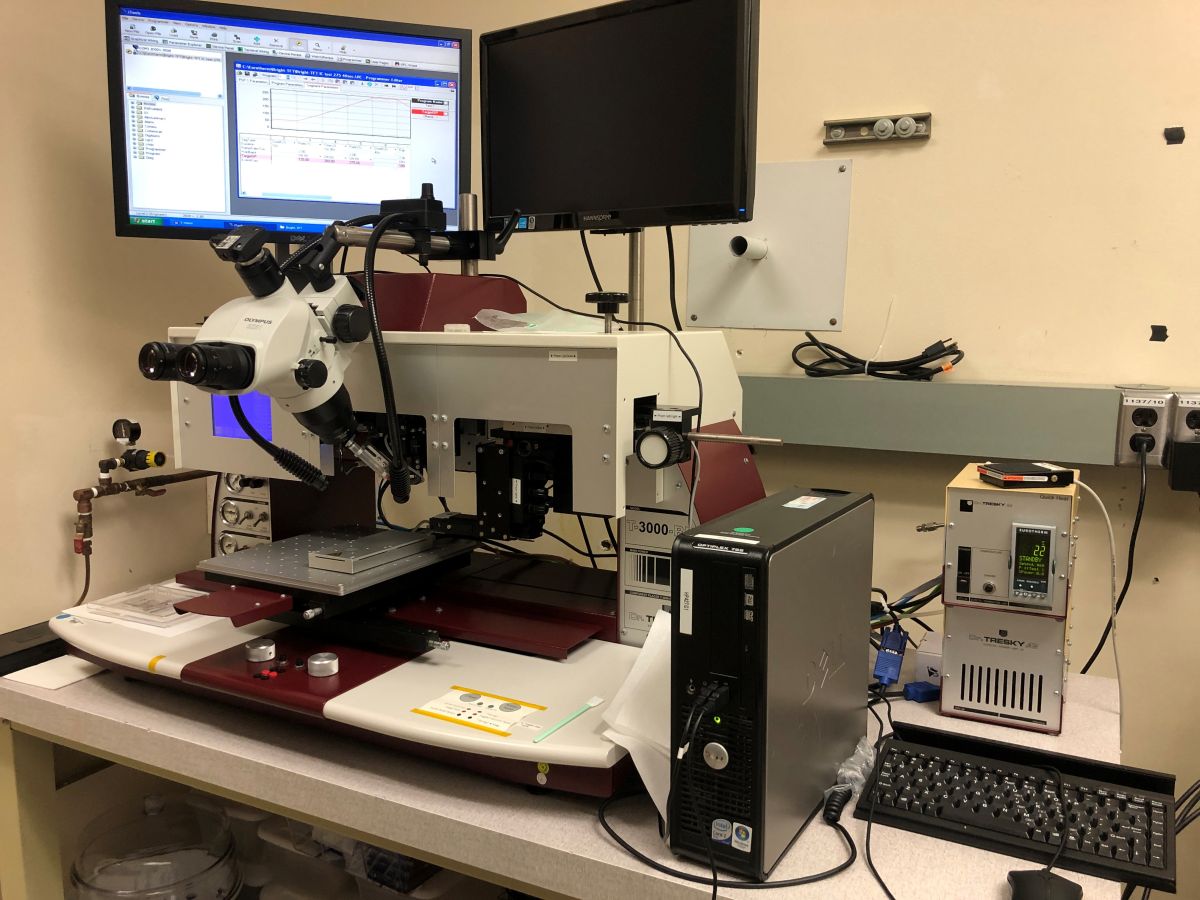

Characterization

- Ellipsometer

- Interferometer

- Probe stations

- Profilometer

- Wafer bow film stress measurement

- Spectrophotometer

- Atomic Force Microscope

- Scanning Electron Microscope

Packaging

- Wafer backgrind and polishing

- Dicing saw

- Laser bar cleaver

- Die attach pick and place

- Wire bonder

- Flip-chip aligner

Epitaxial Growth

- Gallium Arsenide (GaAs) heterostructure

- Gallium Antimonide (GaSb) heterostructure

- Indium Phosphide (InP) heterostructure

- Gallium Nitride (GaN) heterostructure

- Aluminum Nitride (AIN) / Aluminum Gallium Nitride (AIGaN) heterostructure