SRI Foundry Services

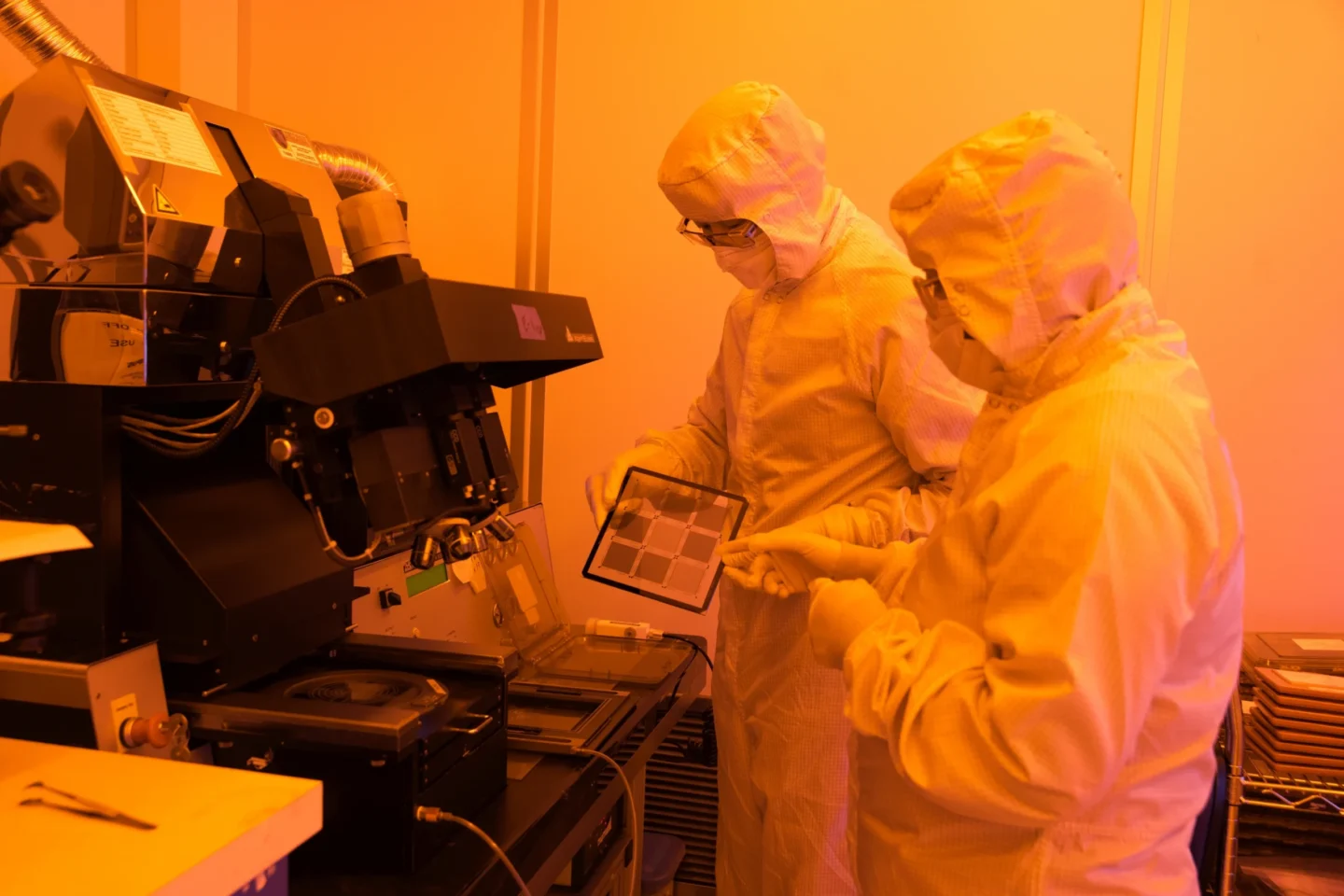

Microfabrication services for your process development, device prototyping, and production needs

What We Offer

SRI Foundry Services – work with our experts to reduce risk and time to market. Take a tour!

Deep Expertise & Experience

Decades of experience leading advanced microfabrication projects, including design support and custom process development for government agencies, startups, universities, and Fortune 500 corporations worldwide.

Custom Process Development

Develop processes, fabricate test devices, and prove your idea, enabling transition to scale up.

Flexible Partnering Arrangements

We handle projects from single film deposition, to full device development, to prototype commercialization, with flexible IP terms customized to your needs.

Our Services

We specialize in customized, expertise-supported services and process development engagements.

Film Deposition

We offer comprehensive thin film deposition services. Whether you require simple single-layer films, complex epitaxy, or process development on your chosen substrate to determine the optimal materials and methods for your device, we can support you at every stage.

Materials:

Dielectric

Metal

Solder

Semiconductor

Processes:

Physical Vapor Deposition (PVD; Sputtering)

E-Beam Evaporation

Thermal Evaporation

Low Pressure Chemical Vapor Deposition (LPCVD)

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

Metal Organic Chemical Vapor Deposition (MOCVD)

Atomic Layer Deposition (ALD)

Screen Print

Electroplating

Etching

We offer both wet chemical etching and dry etching, and have capabilities on etching a wide variety of materials, including semiconductors like Silicon (Si), Gallium Arsenide (GaAs), Indium Phosphide (InP), and Gallium Nitride (GaN) and their associated alloys.

Materials:

Dielectric

Metal

Semiconductor

Organics

Processes:

Reactive Ion Etching (RIE)

Deep Reactive Ion Etching (DRIE)

Inductively-Coupled Plasma (ICP)

Chemically-Assisted Ion Beam (CAIBE)

Xenon Difluoride (XeF2)

Wet Chemical

Patterning

We offer a wide range of techniques and materials for patterning. Our capabilities include photolithography and shadow masking. We work with both positive and negative photoresist, image reversal, lift-off processes, and dry film resist with thicknesses exceeding 100 microns.

Materials:

Photoresist

SU-8

Benzocyclobutene (BCB)

Polyimide

Processes:

Photolithography

Ebeam Lithography

Dry Film Processing

Lift-off Processing

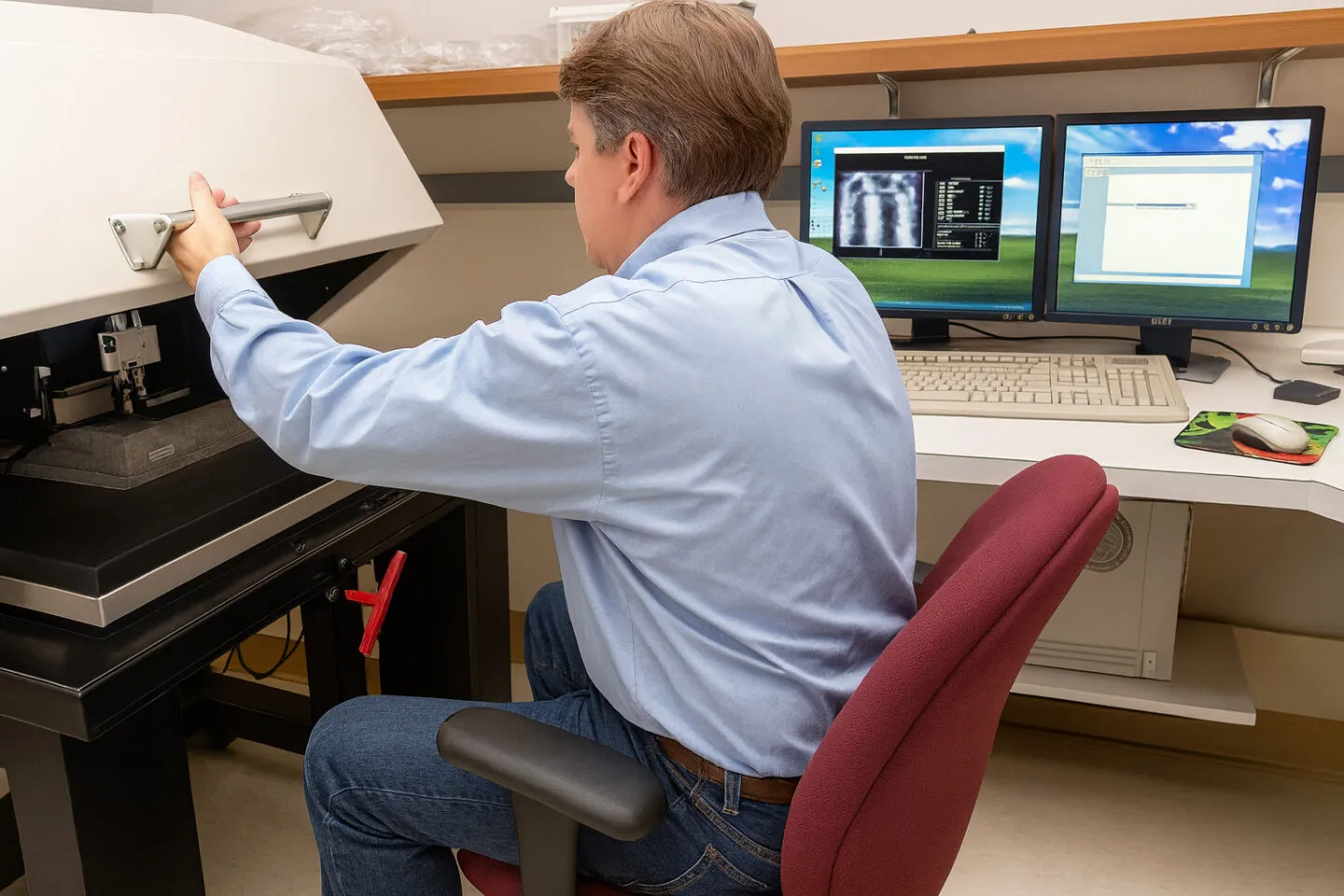

Characterization

We offer a comprehensive suite of techniques and tools for materials characterization. Our expert team skillfully employs these methods to ensure that the materials, processes, and devices we develop for you deliver high performance, reproducibility, and fabrication yield.

Materials:

Thin Films

Laser Diodes

Photodetectors

Heterostructures

Distributed Bragg Reflector (DBR)

Processes:

Scanning Electron Microscopy (SEM)

High Resolution X-Ray Diffraction (HRD)

Photoluminescence (PL)

Spectophotometry

Thin Film Process Monitoring

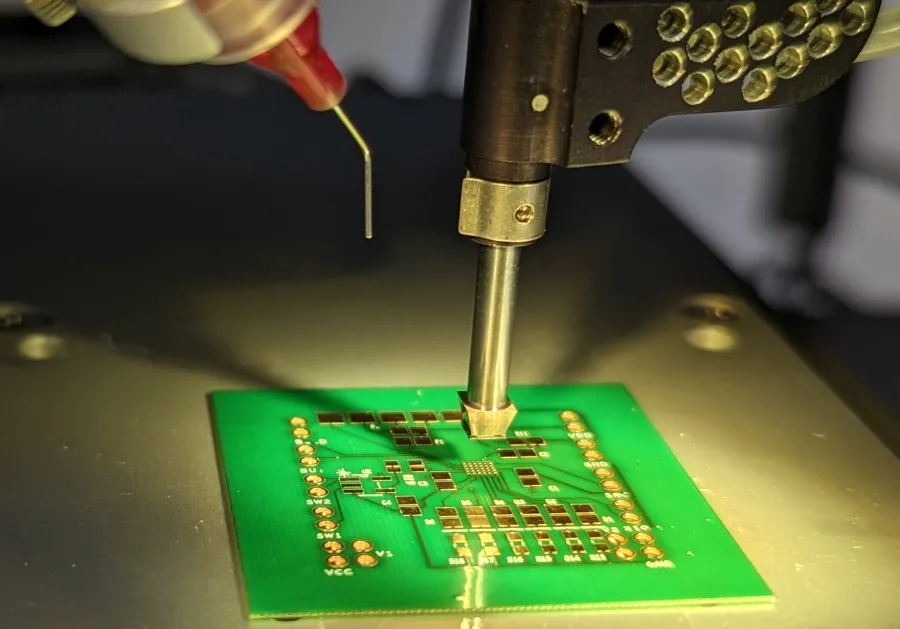

Backend Microfabrication

We offer backend capabilities important for Micro-Electro-Mechanical-Systems (MEMS), photonics, and microelectronics. Our expertise includes thinning substrates such as Silicon (Si), Gallium Arsenide (GaAs), Indium Phosphide (InP), Gallium Nitride (GaN), and sapphire. We can cleave compound semiconductors to form mirror facets, and we can polish edges of cut substrates such as sapphire to form waveguide input/output optical couplers for photonic integrated circuits. We have capabilities for die attach, including flip-chip ball grid array interconnect, and we have capabilities to pick and place micron-size chiplets such as micro-LEDs.

We perform add-on back-end-of-line fabrication on Complementary Metal Oxide Semiconductor (CMOS) foundry wafers. Processes include redistribution lines, interlayer dielectrics, opening buried bond pads on wafer-bonded structures, selective area optical coating, and excimer laser shallow dopant activation.

Custom Process Development

We provide end-to-end custom microfabrication process development services, tailored to meet the unique requirements of advanced device concepts. Our team works closely with clients to translate ideas into robust, reproducible process flows, combining expertise in thin film deposition, photolithography, etching, and packaging. Whether the goal is to demonstrate proof-of-concept devices, refine integration steps, or scale toward pilot production, we design and optimize each process module with precision and repeatability in mind.

Success Stories

See example devices we have developed to help our partners transition new products to market.

View AllApplication Areas

We can provide services to assist in a wide variety of application areas.

Optoelectronics & Photonics

MEMS

Quantum SYSTEMS

Advanced Packaging

Biomicrosystems

Simple 3-Step Process

Submit a RequestSubmit your request.

Just fill out our simple request form letting us know what you are trying to accomplish and the type of services you might be interested in. We’ll get you connected to an SRI Foundry expert.

We confirm details and answer your questions.

After receiving your request, an SRI Foundry expert will reach out to you directly to discuss your request, answer questions, and provide recommendations on how we can best satisfy your requirements.

We generate a quote to help you get your project going.

Once we have worked with you to develop an appropriate Statement of Work that meets your needs and budget, we will send you a quote for your review.